From the Resene ProSelect Technical Information Centre

Colour changes that occur in timbers after they are installed in a building are due to many factors including the amount and type of extractives (the materials that can be extracted easily with organic solvents or water), sap vs heart woods, amount of lignin, exposure to light (visible and UV), exposure to oxygen, temperature and any coatings that may be applied. Understanding of colour changes is not complete although general features are well established. The lack of understanding evolves from the combination of the many different factors that influence colour change occurring at different rates under different conditions.

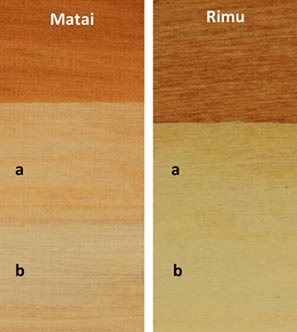

Flooring that has had a carpet rug moved

This is further complicated by variations in timber composition between different trees and growing conditions. Despite the range of factors, there are two dominant factors which we need to be aware of – degradation of lignin by UV light and changes to the extractives. Extractives can be changed by photooxidation (effect of light and atmospheric oxygen) and by reaction with ingredients of coatings and it is the extractives changes that produce some very dramatic colour changes, even over very short timeframes. The lignin degradation rate is very dependent on timber type (and can be influenced by the extractives present) and typically results in yellowing of the timber over time. Eventually this yellowing may become very dark (oranges or browns) before stabilising. Due to the different colours of heartwood and sapwood in many species, each will undergo different colour changes.

It is not possible to completely stop colour changes from occurring unless the timber is isolated from the environment. Obviously a timber floor is exposed to a range of environmental conditions so the best we can expect is to slow changes or limit the extent of colour change. Many of the factors listed above are not easy to change and are related to the timber itself, therefore selecting a timber that is more stable towards colour change is a good start, but not always practical. All is not lost if a less colour-stable timber is being used, as there are ways to reduce the effects of aging. Primarily the exposure to light plays a large role in colour changes as described earlier and this can be controlled to a large extent through design choices, coating choices and positioning (and regular re-positioning) of furniture.

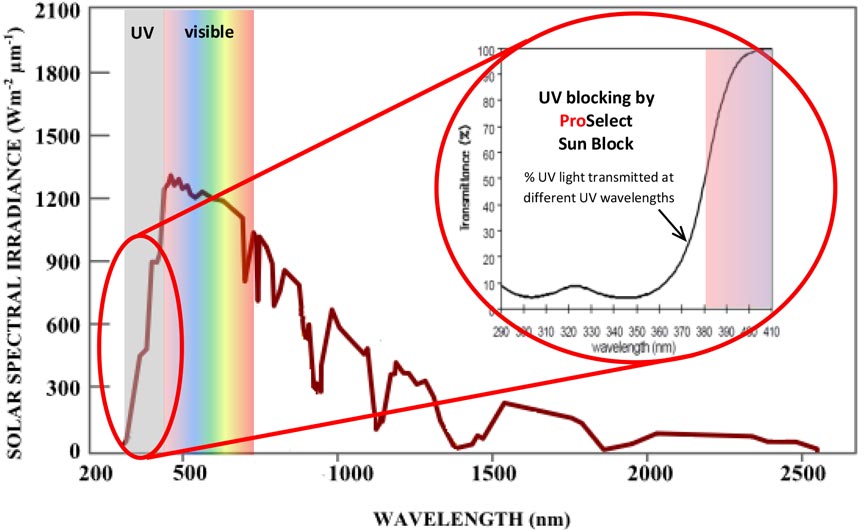

Using a coating containing UV light-blocking materials is an excellent strategy. ProSelect Sun Block is an additive containing UV light-blockers that can be added to the Resene ProSelect coatings to help reduce light induced colour change. The use of some stains also helps protect the timber from light and using these in conjunction with UV light-blocking materials in coatings results in additional protection. It is also possible to bleach the colour-forming extractives before coating the timber which then reduces the colour changes associated with these materials and also allows excellent whitewash effects and more vibrant stain colours to be produced. Bleaching does however have the effect of pronouncing yellowing changes caused by other mechanism such as UV light degradation of lignin.

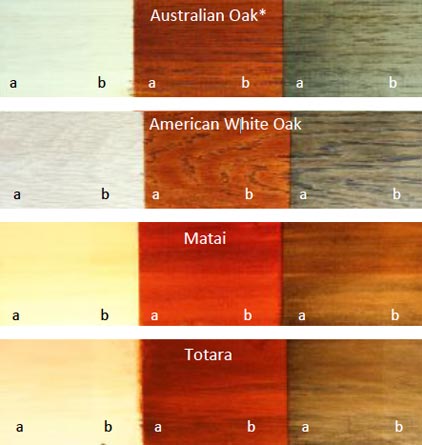

Photographic examples of colour changes occurring in common timber flooring materials are provided for reference including the effects of UV-blockers, stains and bleaching. Note that successful timber bleaching requires a specific type of bleach, not the hypochlorite found in household and industrial products. Resene recommends Rustins Wood Bleach. Further details about colour changes and the effects of stains and UV light-blocking materials are provided after the photographic examples (for readers interested in strategies to manage colour change and to improve fundamental understanding).

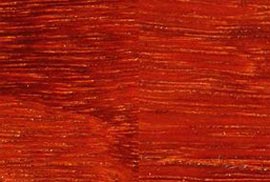

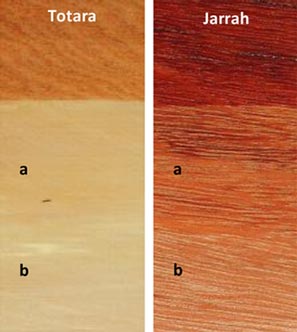

Left side = no Sun Block | Right side = with Sun Block | (6 weeks interior exposure)

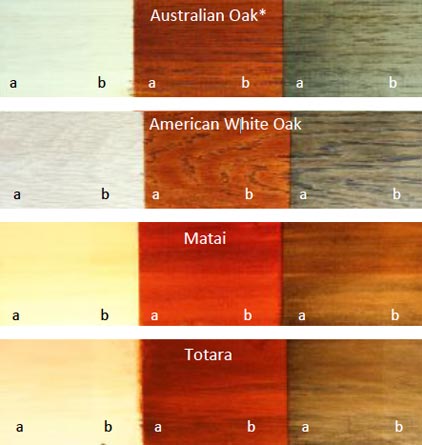

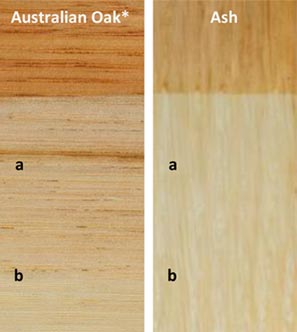

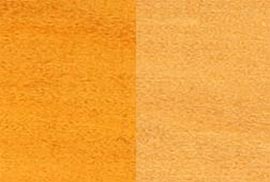

*aka Tasmanian Oak / Victorian Ash

a = uncovered | b = covered | (6 weeks interior exposure) | *aka Tasmanian Oak / Victorian Ash

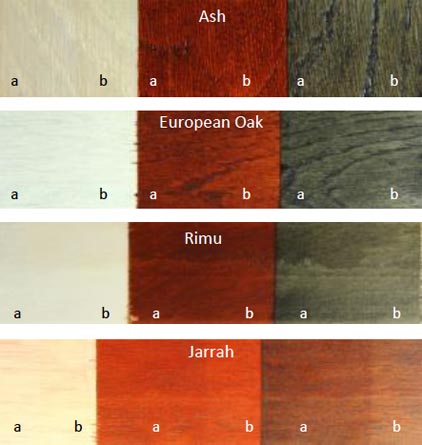

Top of each timber sample unbleached | a = single bleaching step | b = second bleaching step | *aka Tasmanian Oak / Victorian Ash

Left side = no Sun Block | Right side = with Sun Block | (6 weeks interior exposure) | *aka Tasmanian Oak / Victorian Ash

*aka Tasmanian Oak / Victorian Ash

a = uncovered | b = covered | (6 weeks interior exposure) | *aka Tasmanian Oak / Victorian Ash

Where does the initial wood colour come from?

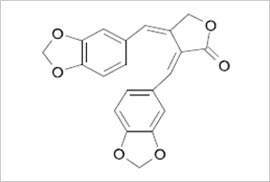

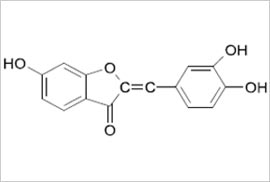

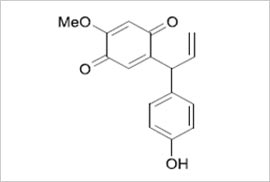

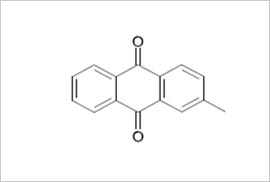

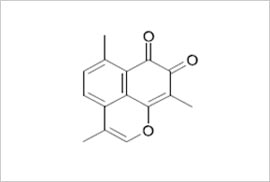

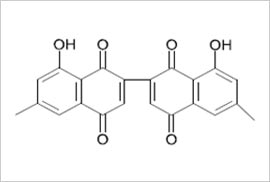

The main components of wood (the cellulose, hemicellulose and lignin) are not highly coloured. Colours, along with other properties like odour and decay resistance, are produced by other materials in the timber, primarily grouped together under term extractives. These make up typically 1-5% of the timber but may be more than 10% for some tropical species. The name extractives comes from the ease in which these materials can be extracted from timber by wet processing typically using water (neutral, acidic or alkaline) or organic solvents. While there are thousands of extractives, the ones responsible for colour make up only a small fraction of the total. The chemical structure of some of these coloured extractives are shown in the figure below along with the characteristic colour they produce.

As a tree grows the inner parts become a repository for many of the extractives. Since extractives become concentrated in the heartwood it should be no surprise that heartwood has more vibrant colour compared to sapwood. Degradation of these extractives results in reduction in colour intensity and eventually loss of the particular colour. Some coloured extractives also degrade slowly due to reaction with oxygen and free radicals formed in the timber and this can eventually result in colour loss deep into the timber. Other coloured extractives may remain intact below the outer surface and mechanical removal of the surface exposes fresh coloured material. In some species other extractives such as acids, resins and waxes are responsible for problems encountered with coatings. These include slow curing and poor adhesion.

Timber is a natural organic material – its main constituents are made up of carbon, hydrogen and oxygen. Like most organic materials, nature and time are able to change them through a range of processes.

Focusing on light-induced changes, UV light causes more colour change than visible light simply because it has much higher energy. This is the same energy responsible for sunburn on skin. With exposure to light it is generally observed that light-coloured softwoods such as pine become more yellow and darken and darker woods often lighten. Of course there are exceptions where darker woods darken (cherry and mahogany) and there are some comparatively light-stable light-coloured timbers such as ash, oak and maple. These are generalisations but the yellowing is caused by lignin being degraded while lightening of darker timbers is likely to be due to breakdown of coloured extractives. When these different processes combine things become complicated.

The particular extractives of most importance for colour changes after installation are those comprising phenols (this group includes the various tannins) and quinones which are oxidised forms of certain types of phenols (the lignin also comprises phenolic materials which are linked to the previously discussed lignin degradation colour). Both of these extractive types range from simple to complex forms and change colour when their chemistry is altered. Light alters the materials by being absorbed and once absorbed the light energy is channelled into breaking and making chemical bonds. New molecules are formed and these new molecules have different colours or no colour at all. When combined with oxygen in the atmosphere some of these new molecules can be highly reactive and unstable and accelerate colour changes through chain reactions.

There are several reasons for this. Firstly, coatings displace air from the surface of timber and this changes the way visible light interacts with the surface with less light being scattered. When light is scattered from an object it appears white or light (think clouds) so a coating reduces the lightness of timber. Typically people will say the timber darkens. Better coverage and penetration of the timber fibres increases the darkening (less light scattering). Solventborne coatings are well known for this effect and the German word anfeuerung, meaning accentuate, is often used in the coatings industry to describe it. Coatings may also have an inherent colour which will be imparted to the timber which also contributes to colour change. Some constituents of coatings can also chemically react with the timber leading to changes. The alkali used in some coatings, particularly in waterborne coatings to improve storage stability and other properties, is able to chemically react with phenolic materials (including tannins and some extractives) which can be enough to change the light absorbing properties, generally forming more intense colours. Typically darker yellows and browns are formed but some extractives may become red or orange. When lighter colours are present from stains or on lighter colour timbers this can be observed as pink. The alkali can also act to accelerate oxidation of coloured materials through reaction with atmospheric oxygen. Other minor coating ingredients include metal-based materials which are also able to chemically react with extractives with the potential to form a large range of colours. In most coatings these are only very minor ingredients used to accelerate curing and do not contribute significantly to the colour. Many waterborne coatings do not even contain these types of materials.

Timber stains and coloured coatings act to reduce the amount of light that reaches the timber surface. The most effective stains/colours will reduce the amount of UV light transmitted in addition to absorbing some visible light.

UV light does more damage since it has higher energy than visible light. There are many different materials for colouring timber and coatings and they have varied effects when it comes to shielding the timber from light. Dye stains typically do not offer much protection from light and often are not colour stable themselves which leads to additional colour changes. Pigment-based stains are generally much more colour fast, especially those based on metal oxide pigments (yellow and red iron oxides and titanium oxide – white) and carbon blacks. In addition, these pigments are excellent at absorbing UV light which reduces the rate of light-induced changes occurring at the timber surface. In most coatings pigments are used to completely block light from reaching the substrate, however for timber floors normally the timber is a feature and will remain visible or partially visible. This of course means that light will be able to reach the timber surface and cause colour changes so timber stains and coloured coatings will only be partially effective at reducing timber colour changes.

The colour of the coating or stain determines which wavelengths of visible light reach the timber surface but not the amount of UV light. Reducing the amount of shorter wavelengths (the higher energy blue and violet wavelengths) passing through the coating will reduce the rate of colour change for some timber species. Red, yellow and brown coating/stain colours absorb these shorter wavelengths and will provide more resistance to colour change for timbers of similar colour to the stain. Blacks absorb all wavelengths of visible light so provide some protection and whites scatter all wavelengths which also provides some protection since some of the light is scattered away from the timber surface. The amount and physical size of a pigment particle determines the actual amount of light reaching the timber surface with, for any particular pigment, more intense colour equating to greater protection. Since blacks tend to be intense in colour, the amount used in floor coatings is not high therefore the protective effect is limited.

Use of non-coloured UV light absorbing materials in coatings (Resene ProSelect for example) also decreases the rate of timber colour change but does not provide protection from colour change due to visible light. Used in conjunction with coating/stain colours these non-coloured UV light absorbing materials are very effective.

There are a range of these materials for different applications. Commonly they are specific organic materials (some nano-sized inorganic types are also available) which have a chemical structure ideal for absorbing only the UV portion of light. After the light is absorbed, instead of the energy being dissipated by breaking and making chemical bonds, the energy is dissipated as heat and the materials have a long lifetime. Only very small amounts of heat are produced, not enough to be detected in everyday use. The figure below shows the energy distribution of light across different wavelengths (at sea level since the atmosphere absorbs a great deal of light before it reaches the ground). The UV portion seems low until it is understood that this energy is capable of breaking chemical bonds whereas the rest of the light is not.

It is possible to reduce the amount of extractives in timber by particular types of processing although typically this is not carried out for flooring. Some treatments that can be carried out on timber after kiln drying are able to remove certain types of extractives or to chemically change them so that their impact on colour change is altered or reduced. Typically these treatments only affect the surface or outer layers of the timber. Ammonia fuming and lye treatments are two such treatments that alter the colour through chemical modification of extractives and other polyphenolics. Another is bleaching. Timber bleaching with household bleach is not suitable for decolourising timber and typically the opposite is found as the alkali in the bleach and the oxidation process forms coloured species. A dedicated timber bleach is required to lighten the surface of timbers and this type of bleach is typically a two-component product which forms a short-lived “super-oxidiser” inside the timber once both components have been applied. Within minutes of application, up to 2 hours depending on timber species and the amount of bleaching components used, the timber lightens dramatically. Repeating the bleaching step can produce even lighter colours. Colour changes associated with the extractives is minimised or eliminated after bleaching although protecting the lighter timber from UV-induced yellowing with a UV-absorbing product and/or an appropriate stain is generally required. Susceptibility to colour change after bleaching is dependent on timber species. The darker colours produced by lye or ammonia fuming are still prone to colour change although the amount and rate of change will vary.

Even when the light-induced colour changes are minimised, there are still other mechanisms which can cause colour change and these are typically not affected by anything under a building occupier’s control. In combination with protection provided by coatings, regularly moving furniture and rugs will allow changes to be spread over a larger area without sharp changes being visible as contrast lines in the floor.

Resene ProSelect Technical Information Centre

Get a professional flooring finish on timber with Resene ProSelect