Technical information:

How to:

View colour/order:

Resene offers clear and simple paint specification guidelines, designed to make specifying the right paint system easier.

Create a One-Line Specification for your project - select either the substrate listed below or refer to 2(iii) One-Line Specifications Index below for a list of substrates. Our Technical Experts can write the specification for you if preferred, based on your brief. Or try out Resene TechSpec, our online specification tool. If you are in doubt about any aspect of your Resene specification, please contact your local Resene Representative or ColorShop who will be happy to assist.

2(iii) One-Line Specifications substrate Index

(1e, 1i) = Cementitious Surfaces

(2e, 2e/i, 2i) = Timber - Hardboard, Plywood and Weatherboard

(3e, 3i) = Timber Joinery

(6e, 6i) = Ferrous Metals

(7e, 7i) = Non-Ferrous Metals

(8e) = Cedar

(9e, 9i, 9e/i) = Matai and Totara

(10e) = Bitumen, Butyl and EPDM Rubber

(11e, 11i) = Baked Enamel Systems, Glass, Glazed Tiles, Polyethylene and Polypropylene

(12e, 12i) = Acrylic Sheeting, Glass Reinforced Epoxy, Glass Reinforced Polyester, Polycarbonate, Polystyrene, Unplasticised PVC

(13e, 13i, 13e/i) = Brick, Terracotta

(14e/i) = Clay Tiles, Decorative Aggregate Flooring, Hard Fired Non Absorbent Tiles, Slate and Stone

(15i) = Fibrous Plaster, Paperfaced Plaster and Solid Plaster

(16e, 16i) = Canvas, Hessian, Scandatex

(17e) = Weathertight Membranes

(18e/i) = Flooring Systems

(19e/i) = Anti-Graffiti Systems

(20e/i) =Textured Coatings

(21e/i) = Paint Effects

(22e, 22i) = Mild Steels

(24e) = New Metal Spray Coatings

For information on paint related problems see the Resene problem solver section

Resene prints brochures, flyers etc on sustainable paper stocks wherever possible. When you download some pdf files from this website they will refer to being printed on sustainable paper stock. This is because they are an electronic copy of what we distribute to our customers.

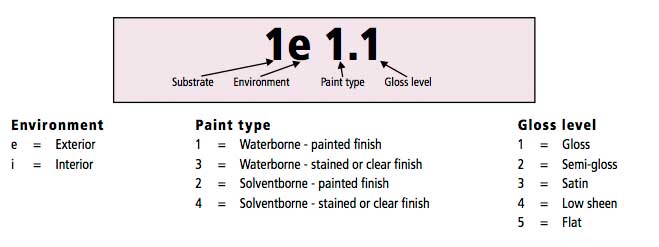

The following is a step-by-step guide to the One-Line Specifications.

Select the Substrateto be painted. (Suppose it is desired to coat the exterior of a concrete block structure.)

Looking up concrete block in the One-Line Specification index will direct you to the appropriate specification sheet. (Specification 1 - Cementitious surfaces in this example.)

Choose the Environment: exterior or interior. (Exterior in this example).

Select the Paint type: waterborne or solventborne paint.

If unsure see, Section 1 (ii) - ‘Selecting Paint Systems’.

Select the paint system (waterborne or solventborne) and go to the appropriate box on the specification sheet. See the comments on the specification sheet for confirmation. (A waterborne system is preferred in this example.)

Select the appropriate Gloss level. Section 1 (iii) covers gloss levels. Also see the Resene Architectural Sample Box. (Gloss is selected in this example.)

You have now reached a unique Resene specification number. This number describes the generic paint system, appropriate for your selected Substrate, Environment, Paint type and Gloss level.

The Resene One-Line Specification consists of a generic specification, a unique specification number, surface preparation, list of products and Data Sheets that make up the selected paint system.

Resene offers clear and simple paint specification guidelines, designed to make specifying the right paint system easier.

Writing specifications can be a time consuming process, particularly when new substrates or coatings are desired. With endless combinations of substrates and materials, it is often difficult to know which system is the best system in each situation. One-Line Specifications will not be suitable for all projects. Resene also offers a customised specification process where Resene technical experts will write a specification based on your brief. If you are in doubt about any aspect of your Resene specification, please contact your local Resene Representative or ColorShop who will be happy to assist.

To view specifications and data sheets you will need Acrobat Reader. All surface preparation and data sheets highlighted in light blue in the pdfs are clickable links - simply click on them to view the appropriate surface preparation or data sheet.

To create a One-Line Specification for your project select either the substrate listed above or refer to 2(iii) One-Line Specifications Index for a list of substrates. Once you reach the appropriate specification page simply read through the information and use the tables to determine interior or exterior exposure, solventborne vs waterborne, desired gloss level and so on.

Every painting contract has its own peculiar set of problems for which these specifications may not provide all the answers. Resene welcomes the opportunity to assist in drawing up customised specifications to ensure maximum benefits from using the Resene range of products. Expertise is available in the fields of corrosion protection, weathertightness and decorative effects. Specifiers are encouraged to use the freely available expertise at every opportunity.

Resene has had no other goal since its inception than to independently design coatings for use in the local environment, on locally produced substrates and designed in our unique manner. Our experience, along with our manufacturing facilities with ISO:9001 and ISO:14001 certification, enables Resene to produce high quality products for consistency and performance.

Resene Engineered Coating Systems

Resene offer a range of protective, industrial and marine coatings, capable of dealing with on and offshore corrosion and protecting many substrates in aggressive environments. For harsh and demanding environments the require the greatest protections, including anti-graffiti coatings, the Resene Engineered Coatings has an extensive range of options.

Expert advice is available from trained field staff in the following areas:

Technical information:

How to:

View colour/order: